How to Improve the Sustainability of your Packaging

Moving towards a circular economy for packaging requires large efforts and cooperation between governments and key players across the packaging industry to standardise materials and recycling systems. This includes not just plastics producers and recyclers, but also brand owners, manufacturers, and retailers.

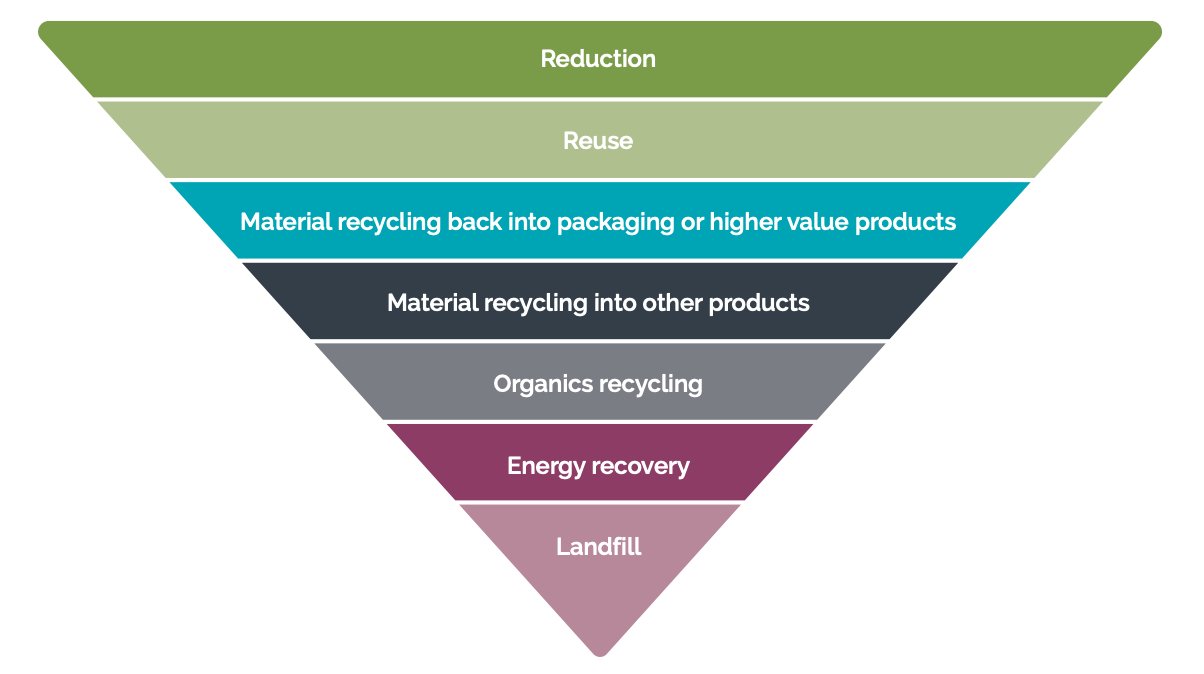

If you are involved in product packaging design, there are a few key things you can do to help boost your company’s sustainability credentials and help tackle the plastic waste issue. The Australian Packaging Covenant Organisation (APCO) has recently released the ‘waste hierarchy’ which provides guidance on actions which achieve the highest potential environmental value. At number one is a reduction of all packaging materials. This is more important, and comes before reuse, recycling, and composting methods. Let’s take a closer look at how this could be achieved.

Evaluate packaging components

Can you make changes to your packaging to use less material, remove unnecessary components, or aid recyclability without compromising product integrity?

Overpackaging is still very often an issue, and packaging design can use too many layers and too many components. The best approach is to lightweight the material to the point where it still does its job, but the unnecessary parts are taken away.

Packaging made from multiple components can cause problems when it comes to recycling, particularly when non-recyclable components are tightly bonded to recyclable materials, making them difficult for consumers to remove, and meaning they contaminate recycling streams. Troublesome components include silicone valves and metal closures on PET bottles, non-removable film lids, and labels covering more than 60% of a substrate surface.

Removing unnecessary plastic is also a good idea as long as the alternative doesn’t have a bigger environmental impact and works to the same effect. Remember that all packaging materials have an environmental footprint so just switching materials is not the answer.

Think about space-saving

Space-saving is crucial to product design and sustainability, as transport costs make a significant contribution to a product’s overall environmental footprint.

Designing products that can easily and effectively slot together, reducing unnecessary components, and lightweighting packaging all go some way to assist with this. Space-saving can also help to reduce the costs of shipping empty product packaging – for example, flexible, recyclable plastic films such as biaxially-oriented polypropylene (BOPP) require significantly less plastic than traditional blow-moulded applications and can be delivered to a filling facility as roll stock reducing overall transportation costs.

By designing products with the logistics chain in mind, you can save an awful lot of effort and energy. Use the logistics chain to its best effect. The more of your product that you can get onto a truck, the lower the carbon footprint.

PrintDATA is here to help

As an industry leader in the field of coding and marking, we are working to minimise some of the risks involved in designing for sustainability by developing laser- and ink-coding solutions for a range of new packaging solutions – including recycled, recyclable, and bio-based plastic packaging.

At the Domino Laser Academy in Germany, a team of technical specialists are working to develop solutions for new single-layer and lightweight plastics, by analysing substrates at the molecular level. A notable example of this is the development of a 9.3μm wavelength ‘blue’ laser tube for safe coding of lightweight, recyclable, and plant-based, non-biodegrading, PET materials.

Equally, the Domino Ink Development and Global Pre-Sales teams have worked to develop a range of ink solutions for single-layer, recyclable plastic films made from polyethylene and polypropylene, including BOPP film for use in food packaging.

Developments into new and improved plastic packaging are likely to continue for several years to come, as such Domino will continue to monitor these trends and respond with innovative technologies to ensure optimum coding solutions capable of handling the very latest substrates.

Wherever you are in your sustainability journey, printDATA is here to help, with experts on hand to advise how best to produce products that will be accepted by retailers, valued by consumers, and trusted by everyone with an environmental concern. Contact us for more advice.