3 Tips to Maintain your Label Printer

Printer failure has a significant negative impact on many aspects of an organisation – user frustration, lost productivity, increased cost of repairs, lost opportunities, and even impacting a business’s reputation. This becomes more obvious when the value of the label is considered within the process or the product’s supply chain, for example the value of a rejected shipment if the pallet’s barcode label doesn’t scan or the customer dissatisfaction and cost of goods lost in transit if delivery information is illegible.

Correct printer use, as well as the day-to-day cleaning and maintenance procedures will keep the print crisp and clean and the printer running well. Choosing the right media will also help prolong the output of the label printer. And, just like a car, label printers also need to be serviced regularly by an authorised technician to operate efficiently.

Clean regularly

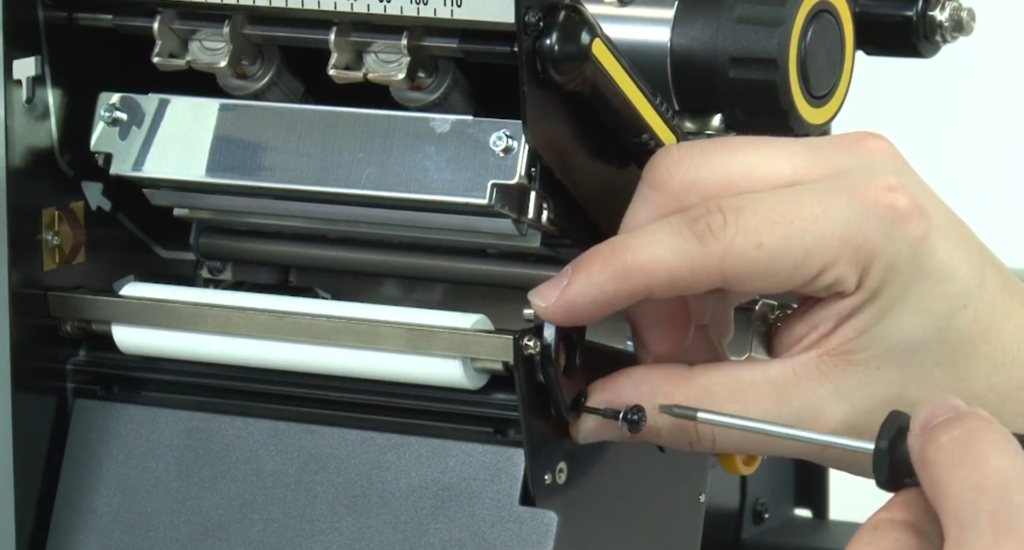

There are many parts in a label printer that only function optimally when they are clean. The print head is the most important part and is also very delicate. If there is any dust or label residue on the print head, it will have a bad effect on the print quality and could cause permanent damage. The platen roller is the rubber roller that sits directly under the print head. We recommend cleaning both parts every time you change the label or ribbon rolls. All it takes is a quick wipe from end to end with Isopropyl alcohol on a cloth or cotton swab. To clean the platen roller, you will have to turn off the printer and rotate the roller as you wipe it. It’s something that takes as little as one minute and yet it will help maintain print quality and extend the life of your printer.

It is important to also keep the media sensor and media path clean (the path the labels feed through your printer). As paper dust and other contaminants accumulate inside the printer, the particles can be pulled through the media sensor to the printhead, causing inconsistent label detection and voids in the print. To prevent these problems, check and clean these once per month, or more often if your printer operates in a harsh environment. Just use compressed air, a soft brush or even a vacuum cleaner to remove all dust and debris from inside the printer and the media sensor. Then, using Isopropyl alcohol on a cloth or cotton swab, wipe all components that the labels will touch on their way to the printhead.

Right media

If your procurement team hasn’t already worked closely with a label printer expert to ensure the right product labels and printer ribbons are chosen for each manufactured good, then you need to pick up the phone and call us or email us to schedule a consult right now. It can cost tens of thousands of dollars to get a label set up or changed in a bill of materials. You need to get it right the first time.

In fact, our support team is often called in by organisations to help diagnose and correct “printer” performance issues that, upon further investigation, are discovered to be the result of incorrect supplies selections. In most cases, customers thought they had picked out the right labels for their products (on their own) only to find out quickly, after a lot of time and money was spent on the implementation, that they had not. Or there was a label-ribbon compatibility issue.

It is so important to only use labels of good quality and matched to your specific application. Because they come into constant contact with the print head, poor quality labels will lead to early print head failures due to adhesive bleeding, unfavourable perforation cuts or other things.

Another downside of unsuitable labels is that you may need to use excessive darkness and heat settings to compensate for poor quality. Unfortunately, increased heat and residue will eventually cause damage to the print head, therefore reducing its lifespan. Furthermore, if the heat setting is too high, it can break low-temperature wax ribbon.

Ribbons come in all sorts of types and quality. Don’t automatically use the cheapest you can find, as this will affect how often you need to spend money on a new print head. Choosing a higher quality ribbon will give you a nicer looking print and will mean the print head lasts longer.

There are three main types of thermal ribbons that are used today: wax, wax-resin and resin. Knowing which one to use can be difficult, so it is best to contact a printer expert to help you decide.

Don’t try to choose your consumables alone. It’s not worth the risk, especially given how much time and money you’ll save by consulting with experts who have decades of experience in labels and other printing solution components. Call a trusted supplies provider today to ask for guidance. Even if you think you’re using the right labels and ribbons today, it doesn’t hurt to double check. If you’re already buying the right supplies, great! If not, you’ll be able to make the change you need to protect your reputation with customers, avoid non-compliance penalties, improve your operational efficiency and reduce operating expenses.

Service regularly

While our tips will help you reduce downtime due to label printing errors, we understand that you might have a lot of other machines and projects to take care of. We recommend that you set up a maintenance contract with a local service team in your area. Certified technicians will make sure to perform scheduled maintenances and necessary repairs according to the manufacturer’s instructions and warranty notes.

To reduce the total cost of ownership of label printers, regular maintenance and servicing can be regarded as an ‘optional extra’, or an unnecessary expense. Although this may provide short-term cost savings, this strategy will cost more long-term.

There are a lot of adjustments and settings that aren’t mentioned above but could be the reason for a decline in print quality. You could see an image that fades across the label, ribbon wrinkling, poor label tracking or short printhead life. These could be because of incorrect media width adjustment, incorrect printhead pressure adjustment or sudden increases in the darkness adjustment. Adjustments to these printer settings are best done by a service technician, to protect the life of your label printer and printhead.

PrintDATA’s maintenance contracts can be tailored to your individual needs, from regular servicing to once-off optimisation visits. Contact us for more information about all things labelling and printer maintenance.