3 Keys to a Good Pallet Label

Did you know that a single barcode on your pallet is used every step of the way from the manufacturer to customer? A Serial Shipping Container Code (SSCC) is a barcode that uniquely identifies an individual logistic unit, such as a pallet or case. The manufacturer will apply the SSCC to the pallet, the transport company will use it for internal controls and tracing, the distributor receives the SSCC and uses it for internal controls and outbound shipments. From there the next transporter will track the SSCC for tracing purposes and finally, the end customer will receive the original SSCC and use that for tracking the goods inwards.

Pallets must be labelled correctly with an SSCC and other codes containing details of the product and its quantities, including supplier details, serial numbers, batch numbers and more. In a warehouse or distribution centre scanners will be required to read these codes quickly and without fault. When printed labels are applied correctly on multiple pallet surfaces, they are easier to scan; thereby improving logistical efficiency, inventory control, and saving both time and money.

There are three key elements to a pallet label that is both practical and compliant: size, content, and application. Here we summarise the somewhat complicated GS1 Guidelines and combine them with what we have learnt from more than 15 years in the label printing industry.

Size

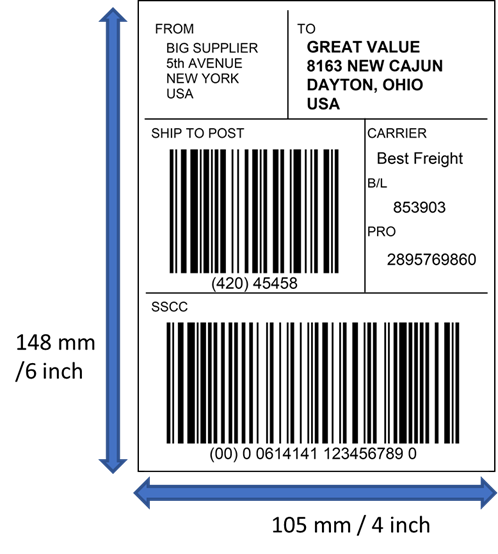

Figure 1: dimensions A6 / 4 x 6 inch label Source: GS1

The size of the label is important, but not bound by regulations as much as practicality. The business requirements for most users of GS1 labels are met by using one of the following:

- Compact label

A6 (105 mm x 148 mm) or 4 x 6 inch, which is particularly suitable when only the SSCC, or the SSCC and limited additional data, is encoded.

- Large label

A5 (148 mm x 210 mm) or 6 x 8 inch, suitable when additional data such as trade item data are needed. Applied for example on international shipments.

Most stand-alone label printers can print a maximum width of 4 inches, so it might suit you best to stick to A6 if possible.

Labels larger than A5 are also allowed but it is usually not worth the extra cost over time.

Content

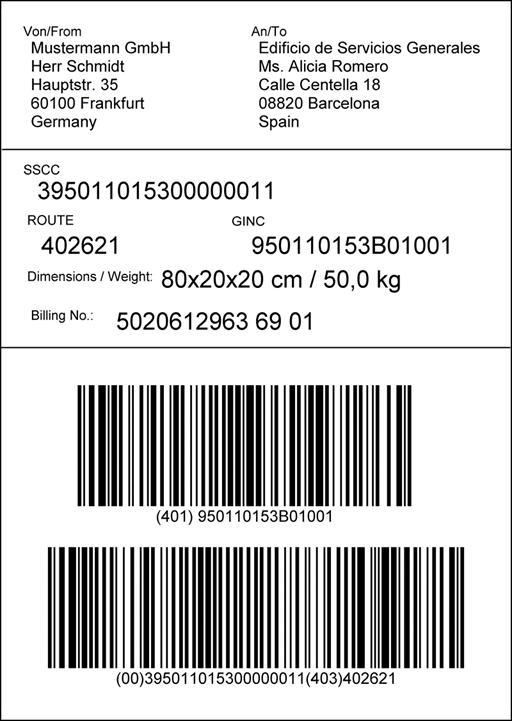

Figure 2: Example of a GS1 logistics label Source: GS1

The label will contain both human-readable text and scannable symbols, such as supplier details, Serial Shipping Container Code (SSCC), product description, product GTIN, carton quantity on pallet, plus code date information and batch number (if applicable).

Carriers (Logistic service providers) will often not have access to electronic information stored in an SSCC. For them the inclusion of additional information on the label is important. Customers or receivers may also not always have access to all the required information. Typical information used for transport includes ship to postal code, consignment number, and carrier-specific routing and handling information such as a routing code. Typical customer information includes the ship-to location, ultimate consignee address, purchase order number, shipment number, etc.

When it comes to the label content, ensure you meet all of the following standards:

- SSCC is unique for each pallet and has not already been issued in the last 12 months

- Both SSCC and product information barcodes are printed in the correct format

- All bar codes are at least 32mm in height and horizontal orientation

- Barcodes shall be printed with quiet zones (or light margins) on each side.

- Human readable information is located below barcode symbology, is no less than 3mm in height, and is clear and legible

Application

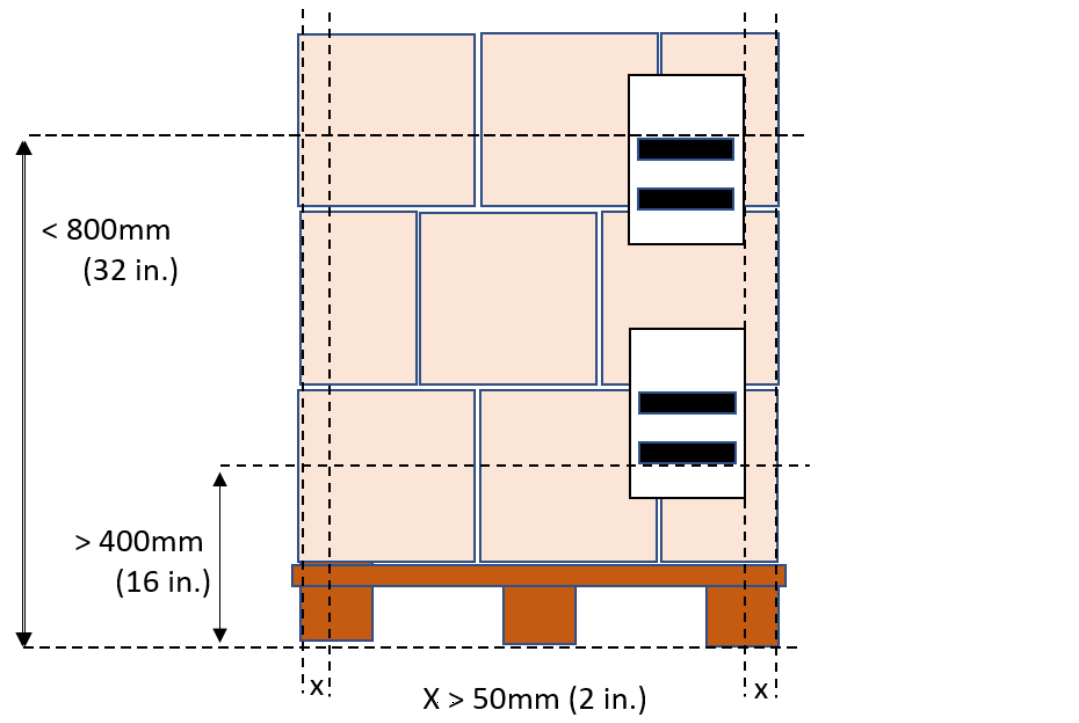

Figure 3: Example of label placement on pallets Source: GS1

No matter how perfect the content and size of the label, if it’s not in the right place, a scanner will not be able to read it. GS1 Australia and the grocery and liquor industry recommend:

- Barcodes should be positioned at least 400mm and less than 800mm from the base of the pallet. For pallets less than 400mm high, the barcode should be placed as high as possible while protecting the barcode. It should be positioned between 50mm and 100mm from the right-hand vertical edge.

- Two identical labels per pallet are recommended, on opposing fork entry sides.

- Vertical position, not crooked, creased or angled greater than 5 degrees

- Barcodes must be horizontal, i.e. the lines and spaces must be perpendicular to the base of the pallet.

- The label must be placed on the outside of stretch-wrap for full pallets

- When multiple pallets are stacked and stretch-wrapped on the same footprint, the pallet labels should be applied underneath the stretch wrap as this will be cut away upon delivery into the distribution centre

- When multiple pallets are stacked and stretch-wrapped individually, the pallet label should be applied over the stretch-wrap

The solution

Figure 4: The M230i-P150 delivers a robust flexible and automated solution for the final step of your production process

There are so many guidelines and rules, how do I achieve the perfect pallet label every time?

It all comes down to the technology you use and how it is integrated into the end of your production line. Pallet labels can be applied at the point of manufacture or at the point of dispatch. They can be applied automatically using a pallet applicator or manually using a label printer.

If you opt for an applicator, this should typically be installed at, or immediately after, the pallet wrap station. You can integrate your applicator with a coding management software like Domino’s QuickDesign on the packaging line to automate the print, apply and verify process. This enhances the efficiency and accuracy of the entire process.

It is a good idea to choose an applicator with an integrated check-scanner, so the labels are scanned for errors immediately after printing. This reduces the chance of traceability issues further down the supply chain process.

Ask the experts

PrintDATA provides a large range of label machines for a variety of uses and sectors. If you are looking for anything from a label printer to label print-and-apply technology, we have a solution for you. All of our printers are available with coding automation software, allowing you to integrate your coding machine into existing systems, and fully automate the pallet labelling process.

Please get in touch to discuss your individual requirements with one of our experts, who will guide you through the selection process, to ensure that your labels are always fully complaint and scan every time.