Minimum Viable Product in an Agile Healthcare Facility

Why do I need to use the Minimum Viable Product (MVP) concept to develop an Agile Healthcare Facility?

Minimum Viable Product (MVP) is an agile term used to describe the minimal input required to develop a new product or solution. It is critical to minimize the impact and cost of a solution that has not been used or tested in a specific environment. Therefore, we use this concept to validate and address concerns that have developed in a specific area of your facility at a minimum input of time and dollars.

Working in a small business provides a natural environment for MVP in product development. Because there is no large research and development budget, everything is usually completed to a minimal standard anyway. However, in larger corporations and healthcare facilities often large amounts are spent on projects that have great expectations from management, but no real expectation for the users of the product.

Developing the imed16 cannulation trolley for the Department of Health WA.

WA Health requested printDATA to work with them in developing a mobile solution for printing labels that could be easily applied to blood vials. In theory, this was a simple request, however, it required integration into existing healthcare software along with consideration for ease of use for the clinicians.

DEVELOPMENT

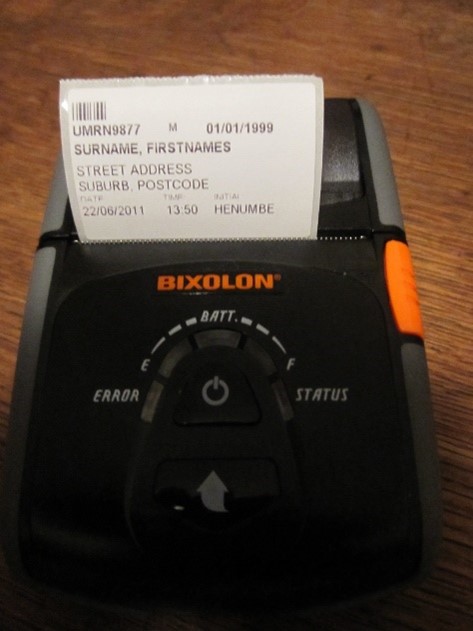

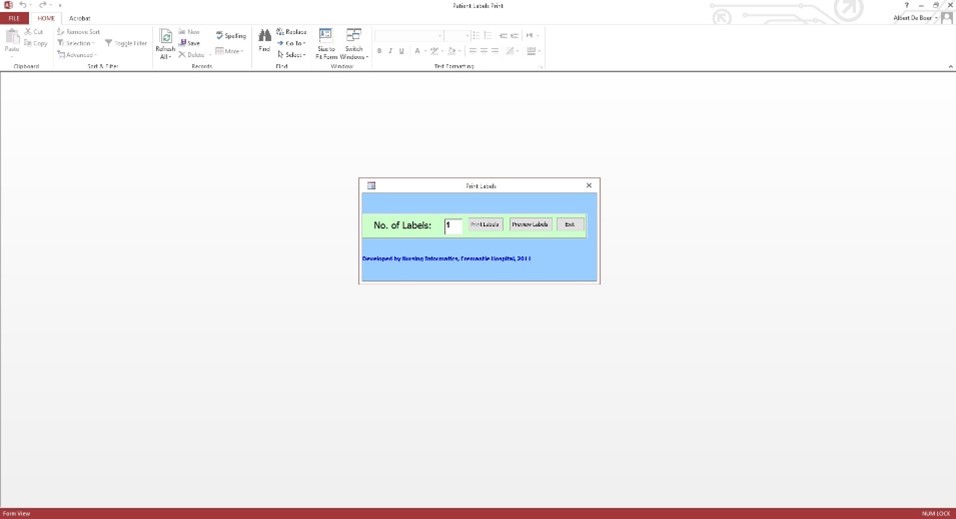

The first MVP was therefore a mobile printer along with a simple Access database that held patient data. This solution cost no more than a $500 printer and limited time to develop a simple database.

ENHANCEMENT

The next step in our development of this product was to set up the required devices on a trolley. For this process, we used an old laptop, mobile printer, barcode reader, and RFID tag reader. This iteration of the product allowed for the healthcare professional to scan their user ID on the RFID reader to log in to the healthcare system to access the clinicians’ details. It also allowed the clinician to generate a label for the blood vial by simply scanning the patients’ wristband barcode.

LIVE TRIAL

Now that we had the concept of printing labels proven and working, we worked with the clinicians to develop the mobility of the project. While the stainless cart was a good concept the hospital needed a solution that would allow the operator to run 24/7. Using Agile methodology, printDATA tested multiple powered carts to find the most suitable for the required purpose. They settled on a solution that was both compliant and convenient, and WA Health purchased 6 of these to trial in their hospitals.

CLINICIAN FEEDBACK

As the project gradually developed, printDATA sought feedback from the clinicians on the floor as part of their ongoing Agile product development. They made it clear that to the team that there was insufficient storage and a lack of room on the existing trolley. We therefore worked closely with WA Health, developing imed16, a custom trolley design and build that satisfied these requirements. WA Health ended up purchasing 40 of these units for their emergency departments in Western Australia.

Does this mean it is no longer an MVP?

Not really, as this was the minimum requirement to thoroughly test this product in a live application. It required a rigorous test over a period of time. It met the needs of the customer and is still being used by their clinicians. However, using the agile methodology I am sure there will be additional changes and tweaks to this unit as it continues to develop.

The Minimal Viable Product (MVP) is the most agile method of satisfying a customer’s requirements.