What is the Future of Coding?

Just like the Slim Dusty song, coding technology has come a long way down the track and got a long way left to go. There is value in looking back, but it’s important to look to the future to make sure we are ready.

Domino Printing designed a simple questionnaire and used it to conduct face-to-face interviews with their customers from a range of sectors, across the world. Here are their findings.

Growth in adoption of laser coding technologies

For the majority of manufacturers and packagers, the coding technology of choice for primary packaging is continuous inkjet. However, the survey suggests the industry can expect global growth in the adoption of laser and thermal Inkjet technologies as we move towards the next decade, with negative growth for continuous inkjet systems.

Laser coding systems offer several benefits to manufacturers. Flexibility is chief among them. You can code human-readable text, graphics, variable and serialised data as well as 2D codes onto a variety of substrates – including cartons, glass, metal and paper. Think high-quality permanent marking with extreme precision and low maintenance.

Significant growth in use of print and apply technology

Print and apply technology is already used extensively for secondary and tertiary packaging. Continued growth is expected in the run well into the future. This trend is largely driven by the increased demand for serialisation, especially aggregation, as well as the need to apply clear, machine-readable codes at speed to trays, cases, shrink-wrapped goods and pallets.

Increased use of 2D codes

Most customers said they planned to increase their use of 2D codes on both primary and secondary/tertiary packaging. It’s easy to understand why. Not only do 2D codes make it easier for manufacturers and retailers to track products through the supply chain, but they also give brand owners a new channel for interacting with the end-consumer. Anyone with a smartphone can scan a 2D code. That gives marketers a way to boost consumer engagement through competitions, discount vouchers and more – gathering valuable data on customer demographics in return.

Flexible control of coding systems

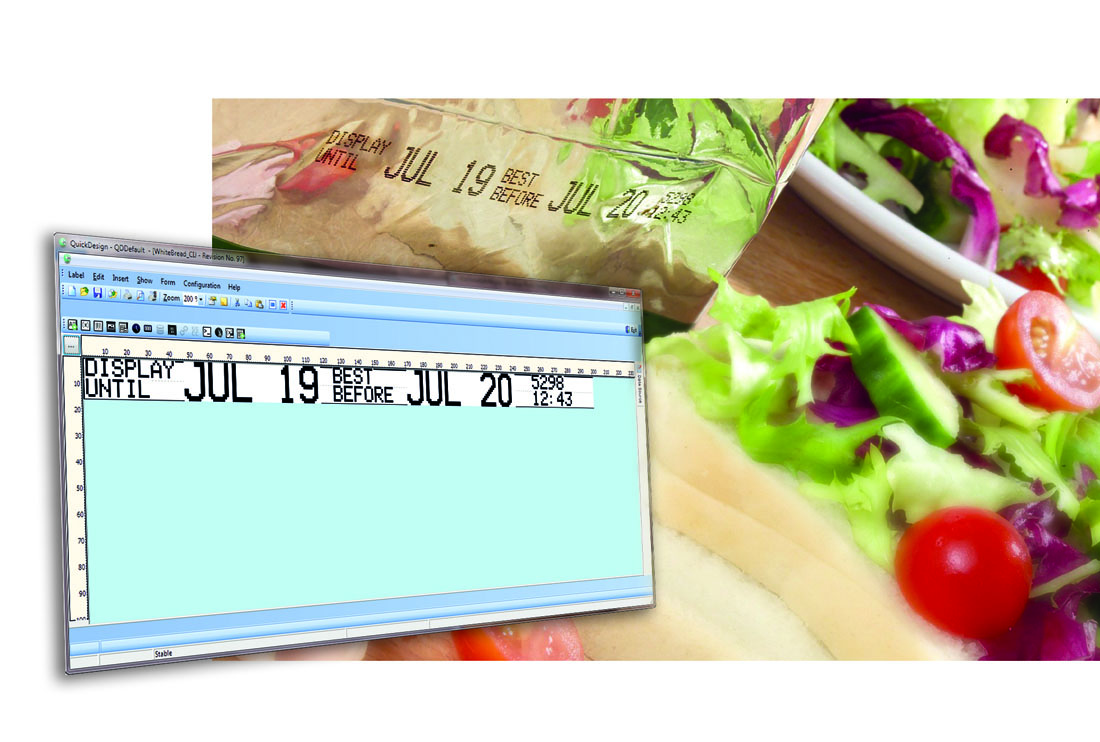

Walking up to a printer control panel to program your next job is all well and good. But wouldn’t it be easier if you could program your coding technology entirely automatically? Our survey suggests manufacturers want to move away from at-printer control modules and towards systems that can be controlled through mobile devices and web apps or straight from the packaging machinery. User interfaces such as Domino’s QuickDesign already support this transition.

More independence, better supplier relationships

Our survey respondents want to rely less on offsite support. They want coding systems that they can install and maintain themselves, without the help of an external technician or engineer. User-friendly technology is the next fashion trend, such as our service-free continuous inkjet printers and ultra-reliable thermal inkjet printers.

However, less reliance on offsite support does not mean customers don’t value expert insight. Indeed, production managers want to build loyal relationships with a preferred supplier of coding technology. Manufacturers want to work with experts who understand their working world, adapting to the nuances of their business and recommending the best technology and installation for the project.

More monitoring of OEE

Productivity, efficiency and throughput on the production line are inextricably tied to the bottom line. That’s why more and more manufacturers and packagers are monitoring overall equipment effectiveness (OEE). Tomorrow’s technology has to be accountable; it has to provide value and it has to enable demonstrable productivity gains to keep consumers happy.

At PrintData we offer live cloud-based reporting of OEE with most of our printers so you can sit back with a coffee in your office and still have all the data you need. That’s a future I’m more than OK with.