Thermal Inkjet vs Continuous Inkjet: Which is Best?

If you are looking to buy a new coder, you first need to decide which printing technology to use. The most common is continuous inkjet but thermal inkjet is starting to become more and more popular. What is the difference between these, and which one is best?

Well, at printDATA we sell both types of printers (along with other printers and also laser coders) so we can be pretty objective about this. The honest answer is that it depends, each print technology has some advantages – it all depends on your application and your objectives. Let’s take a more detailed look.

How they work

With CIJ, a high-pressure pump pushes ink from a reservoir in the cabinet, down a tube to the printhead, through a nozzle on the printhead, creating a continuous stream of ink drops. Within this stream, the printer electrically charges the individual drops. Two high-voltage deflector plates inside the printhead then deflect these drops towards their target location on the substrate. The majority of drops have no charge and so don’t get deflected. These land inside a collection gutter in the printhead and are returned to the ink reservoir to be recirculated.

TIJ systems use a small ink cartridge in the printhead. Each cartridge has hundreds of tiny nozzles built-in, each containing a heating element. When a current is passed through a nozzle’s heating element it warms the ink, expanding it into a bubble. This creates pressure, pushing the ink on the bubble’s surface through the nozzle and on to the substrate. All the action happens inside the printhead which is built-in to the ink cartridge.

Strengths and weaknesses

CIJ

One of the main advantages of CIJ printers is that the print heads are mounted at a distance from the product. This distance is flexible, which allows for printing onto curved or uneven surfaces. If you need to print onto cans, bottles, or pipes, a CIJ printer can be an ideal solution.

CIJ printers are generally able to withstand some of the harshest environments, with IP66-rated cabinets and air-pressurised printheads.

CIJ print-heads can work with a wide variety of general-purpose and speciality inks to accommodate a multitude of applications, such as coloured inks for dark backgrounds, heat resistant inks, washable inks and food-grade inks specifically developed for legal compliance.

However, because ink is constantly cycling through the printer and there are many moving parts, they require cleaning and maintenance more regularly. The large ink drops also mean a low-resolution print, which is not ideal for extremely small text, logos or barcodes.

TIJ

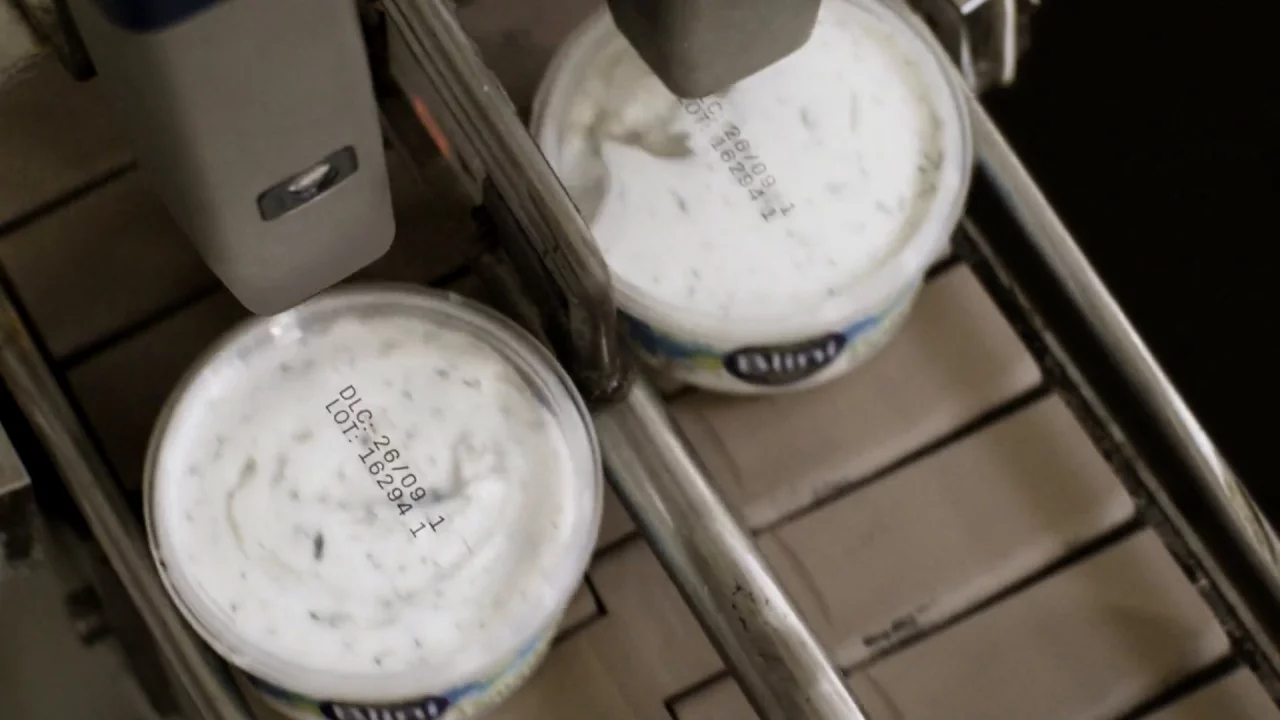

Thermal Inkjet printers can achieve very high-resolution printing at fast speeds. They can print lasting, rub and scratch resistant codes, logos and graphics on paper, card, plastic, metal and many other materials.

Thermal inkjet printers offer a print resolution up to a 600 dpi, which outshines CIJs when it comes to printing high-resolution, easily readable barcodes and graphics.

Thermal inkjet printers are reliable printers that require virtually no maintenance. Since all moving parts are inside the ink cartridge, exchanging the cartridge replaces all printer wear parts. In the small chance there is a fault, replacing the cartridge fixes most problems, which means no production bottlenecks or line stoppages.

Thermal inkjet printers are fast (up to 300m/min) but that is at a low resolution. CIJ printers are more suited to extremely fast production lines as they can print small text at speeds greater than 400m/min.

The bottom line

At printDATA we suggest that you use TIJ where you are printing onto a flat surface where the printhead can be positioned close to the substrate. Manufacturers are increasingly opting for thermal Inkjet as their coding and marking mechanism of choice. A report by Technavio found that the number of installs of thermal inkjet technology is growing at over 7% per year.

Domino’s Gx-Series thermal inkjet printing solutions are versatile, easy to integrate, easy to operate – the perfect fit on many printing applications and substrates. With the latest networking technology and producing graphic code quality, the Gx-Series TIJ printers are ideal not only for batch and date coding but also for complex code formats, check weighing and track & trace applications across FMCG industries.

However, if you are printing at extremely high speeds or printing in a harsh environment, you are better using a CIJ printer. If you are printing onto curved or uneven surfaces a continuous inkjet printer is best. CIJ is also best for high-throughput production lines because of the ink cost savings over time.

For its reliability, cost effectiveness and versatility, CIJ is still the tried-and-tested coding technology of choice for the vast majority of applications. For over three decades, it has imparted health and safety information, helped to move and organise products, and provided brand protection for millions of organisations and consumers.

Among Continuous inkjet printers, Domino’s Ax-Series are a preferred choice. They are simple to install, extremely versatile, and able to print on a wide range of product materials. Ax-Series printers deliver outstanding coding on a wide range of products and substrates.