Printing for Flexible Films – TTO vs TIJ

When it comes to printing real-time data, machine-readable codes, and images on flexible packaging films and labels, thermal transfer overprinting (TTO) has long been the go-to technology. However, there’s a new contender in town that could offer manufacturers a more sustainable and cost-effective solution: thermal inkjet (TIJ) technology. In this blog post, we’ll explore the benefits of the latest TIJ printers for flexible packaging applications.

Understanding TTO Technology

TTO is a coding method that uses heat to transfer ink from a ribbon onto flexible substrates like food and pharmaceutical packaging. It’s specifically designed for flexible materials and is commonly used for printing barcodes, best before dates, and serial numbers. The process ensures high-resolution codes that are easy to read without compromising the visual appeal of the packaging design.

Understanding TIJ Technology

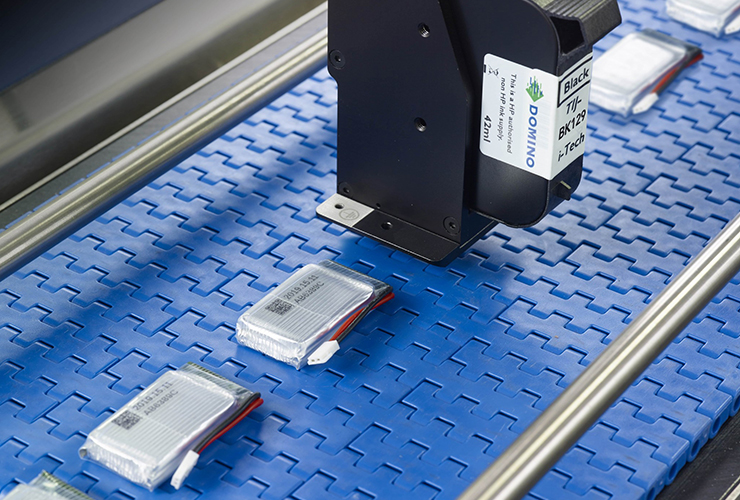

Thermal Inkjet printing is an ink cartridge based, non-contact printing technology. The cartridge uses a built-in printhead to spray ink onto a package or product surface. Unlike TTO, TIJ offers more flexibility in printing accurate codes on various packaging materials, including porous substrates like cardboard and paper, and non-porous substrates like plastics, films, foils, and coated stocks.

Over the years, TIJ technology has undergone significant advancements, resulting in improved code resolution, printing speed, and ink compatibility. Modern TIJ printers can produce Grade A code readability at speeds of up to 300m/minute, depending on the substrate and environment.

Adapting to Changing Circumstances

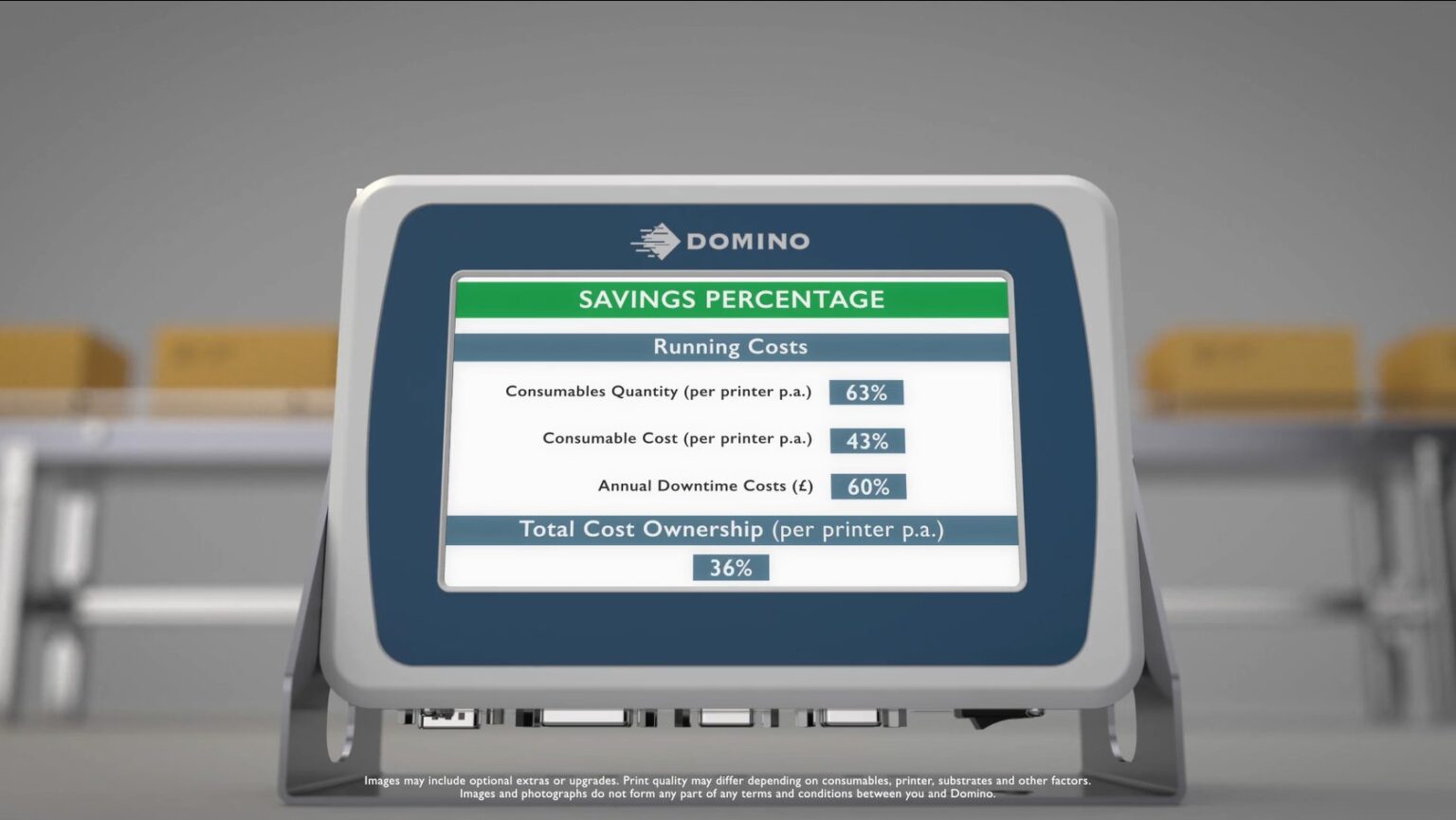

In today’s challenging manufacturing landscape, food producers face supply chain issues, rising energy costs, labour shortages, and mounting pressure to reduce waste and embrace sustainability. To address these challenges, many manufacturers are seeking ways to enhance productivity, minimize waste, and reduce total cost of ownership. For such companies, TIJ technology presents a compelling alternative to TTO printing, delivering comparable code quality while lowering costs and waste.

Key Benefits of TIJ for Flexible Packaging

1. Waste Reduction:

One significant advantage of TIJ over TTO is the reduction in waste during the transition from ribbon-based printing to cartridges. Once printing ribbon has been used, it must be disposed of. Switching from TTO to TIJ can potentially reduce waste from 150kg of ribbon and reels per year to just 4kg of cartridges, representing a remarkable 97% decrease.

2. Cost Savings:

Domino estimates that TIJ can offer a 50% reduction in total cost of ownership compared to TTO for one and two line text coding applications. Additionally, replacing bulky ribbons with compact print cartridges frees up storage space, allowing for more efficient use of available shelf space. The cost savings can be reinvested in value-added factory processes, thereby improving operational efficiency and productivity.

3. Effort Reduction:

TIJ printing requires approximately 25% fewer consumable changes compared to TTO. Changing ink cartridges is also much quicker and easier than replacing ribbons. With Domino’s auto-swap technology, which enables parallel printing from two separate cartridges, there’s no need to interrupt printing when changing ink.

In comparison to TTO applications, TIJ production lines require less maintenance, resulting in reduced downtime and improved team productivity. The time spent on consumable changes, ribbon replacements, and printhead repairs can be significantly reduced, potentially saving up to 75% effort.

Time to Invest

It’s understandable for manufacturers to have concerns about changing their printing technology. However, Domino’s TIJ printers can be installed using the same bracketry as existing TTO solutions, minimising installation and implementation time. Moreover, a typical manufacturer could expect to see a return on their initial investment in less than a year, along with the added benefits of improved operational efficiency and productivity.

Consider Your Needs

While TTO remains the best option for certain applications, especially when printing 1D codes, the latest generation of TIJ printers offers numerous advantages that can drive lean manufacturing improvements and align with the increasing focus on sustainability in consumer goods manufacturing.

To find out how you can save on waste, time, and money with Domino’s TIJ printers, get in touch with us today.