Exceeding High Standards in Industrial Printing

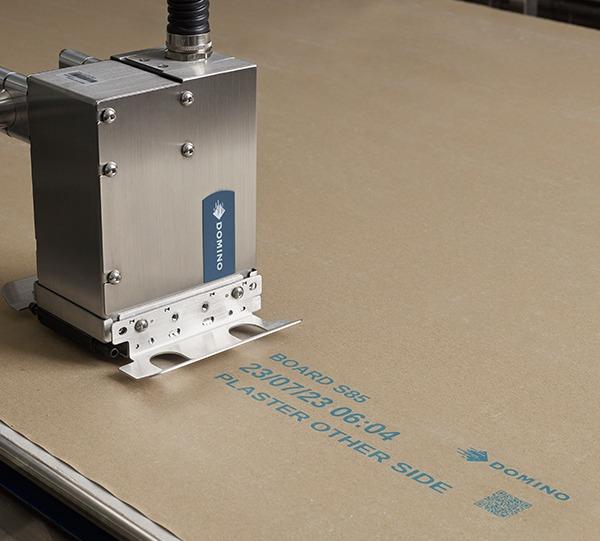

Construction material manufacturers often need to label materials such as wood and plasterboard for identification. This includes manufacturing codes with origin, date and time of production, and batch numbers. These codes help with tracking products and maintaining a record even after they leave the factory. Also, there’s a need for high-resolution branding on products and pallets, such as logos.

Manufacturing sites are known for being demanding and tough. Production lines run fast, leaving little room for breaks. This makes coding products a challenge. The codes must be durable and resistant, and the coding machine must be tough and able to keep up with the high-speed production.

The Game-Changing Solution: Domino Cx350i Printer

Domino has introduced the Cx350i printer, a solution to all these challenges. It’s a drop-on-demand (DOD), piezo inkjet (PIJ) printer that handles large-format, high-resolution printing at industrial speeds (up to 200m/min). The stainless steel printhead is top-notch, producing graphics, logos, text in various fonts, and machine-readable codes. You can combine multiple printheads for even larger print areas.

Quality Inks for Quality Printing:

The ink drops’ size and placement are crucial for good print quality. Domino’s Cx350i inks are specially designed for this printer, ensuring the perfect drop size and placement. Plus, these inks are available in four colours, and made from vegetable oils, supporting environmentally responsible alternatives aligned with a manufacturer’s CSR goals.

Efficiency and Ease of Use:

The Cx350i doesn’t compromise on efficiency. It addresses the need for minimal waste and downtime with a large volume ink reservoir that can be replenished without interrupting production. The touchscreen user interface is user-friendly, minimising the need for extensive training and reducing the risk of errors. No scheduled maintenance is required, and it operates without needing factory air.

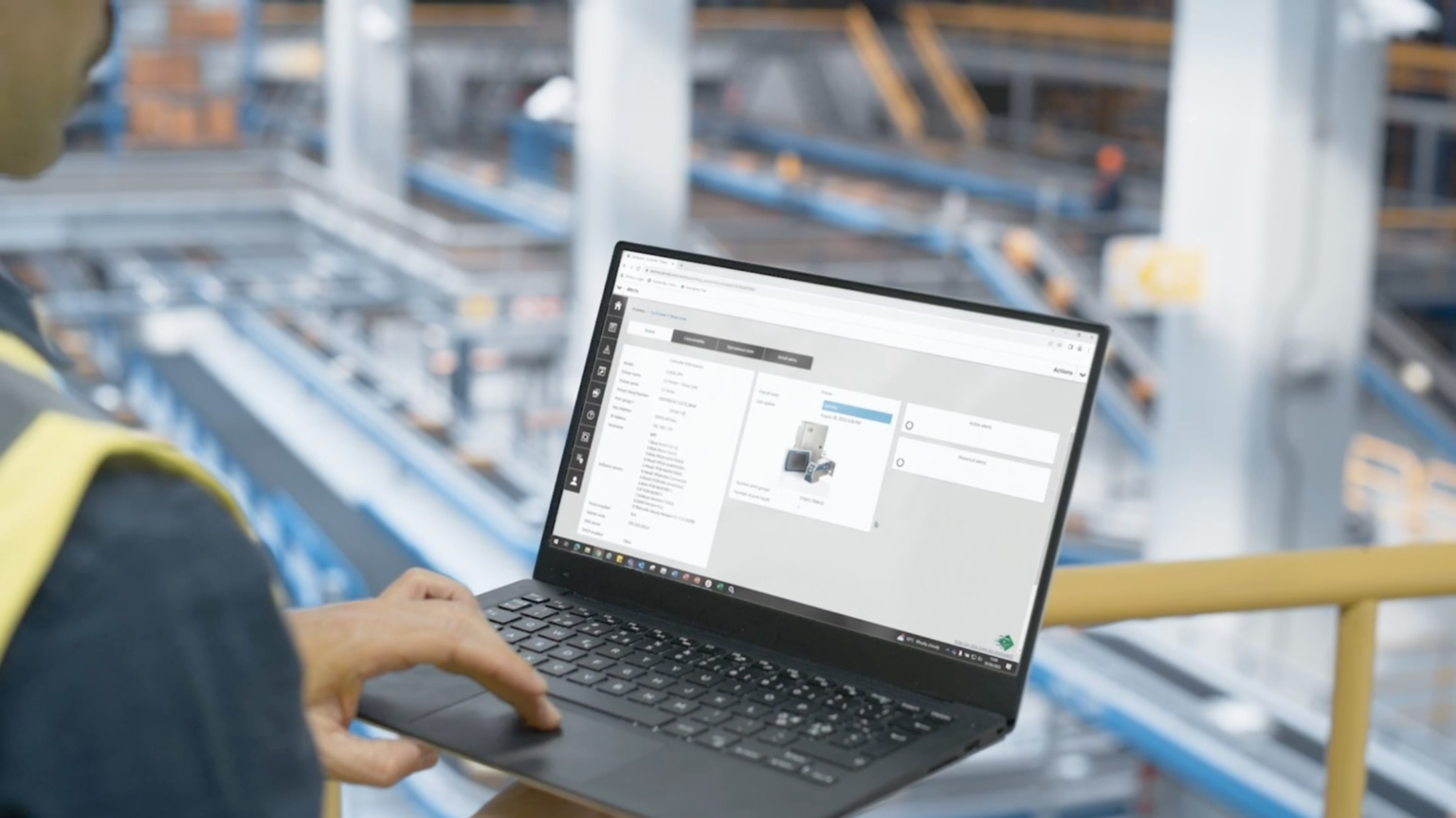

Embracing Industry 4.0:

The Cx350i isn’t just a printer; it’s an Industry 4.0 solution. It seamlessly integrates with various software and systems, offering flexibility and automation. It can connect to label creation packages, MES, ERP systems, and more. The QuickDesign coding automation software centralizes product codes, streamlining changeovers and minimizing errors.

The Cx350i can work with Domino’s code inspection solution, R-Series vision control systems. These automatically validate code presence, placement, and readability without manual intervention, reducing the risk of coding errors and freeing up operator time.

The Cx350i is compatible with Domino Cloud, allowing 24/7 remote monitoring. Online dashboards offer real-time operational insights, and automatic alerts notify when intervention is required or faults are detected.

Top-Notch Support:

PrintDATA doesn’t just stop at providing high-quality products. They offer high-quality helpdesk and field service support. Domino Cloud remotely monitors the printer, ensuring early intervention to minimise downtime and maximise OEE. PrintDATA’s SafeGuard service and support packages provide on-site assistance and remote support from technical experts, ensuring quick resolutions to any issues.

No Compromises:

Manufacturers can now fully embrace plasterboard coding without compromise. The Cx350i, along with Domino’s automation, connectivity, and support solutions, offers a comprehensive solution for large-area, high-resolution, and high-speed production environments.

Domino’s Cx350i industrial printer addresses manufacturers’ key considerations: large-area, high-resolution, and durable codes printed at optimal line speed. With built-in automation to minimise waste and error, it’s a game-changer.

To learn more about achieving top-notch codes in the industrial sector, contact PrintDATA today.