Do I Need An Extraction System For My Laser?

Have you ever wondered why installing an efficient extraction system on a production line is so important when using a scribing laser system to apply traceability codes?

Whether you are using a CO2, UV, or fibre laser, when a laser is used to code onto a product, it removes material from the surface of the product. This creates fumes and debris at the point of ablation that end up in the air and on the production area. Depending on the laser used and the surface of the material that has been lasered, this is to a greater or lesser extent. To remove these substances and keep the production environment clean, an effective extraction system is really essential.

Debris, dust, fumes and particles

Without proper extraction, fumes and particles from the laser would pollute the production environment. It should be a priority to ensure these contaminants do not cause hazards or impact production. Installing an efficient extraction system can not only help comply with safety regulations but also maintain productivity by avoiding build-up of contaminants from the lasering process on the machines and systems.

Consider, for example, the debris settling on the lens of the laser or on a camera system. Ultimately, this contamination can lead to poor coding quality and possibly damage the equipment. This would result in downtime and reduced production for enhanced maintenance requirements, cleaning, and repairs, plus adding repair costs; additionally, it can shorten the life of the production equipment.

In essence, extraction is essential to ensure uninterrupted production and good coding quality. From our experience, an additional benefit is that the laser lens lasts much longer.

How does an extractor work?

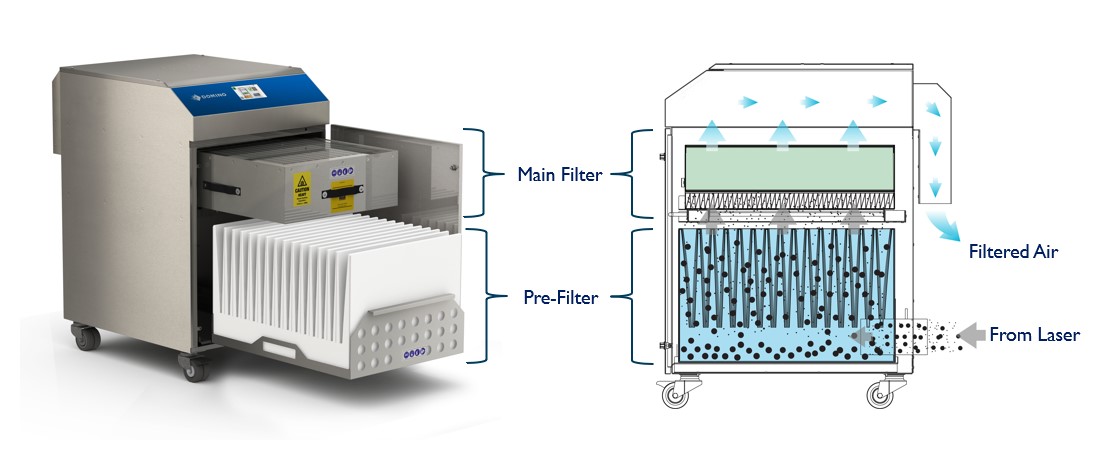

Very simply put, either a shroud, nozzle or hose is positioned close to the point of laser marking to suck the removed debris into the extractor. Here the debris passes through filters that effectively remove the fumes and particles from the lasering process. Afterwards the air either returns into the factory (vent-to-factory) or is removed completely (vent-to-air).

Is your extraction system efficient?

Many companies have already equipped their production lines with extraction units for their laser system. These companies are on the right track. But how do you know your extraction system works properly and efficiently?

Poorly functioning extraction can be recognised by several things, such as increased maintenance required, visible debris on the machines, or poor print quality. Other signs include when the lens of the laser is dusty, or when dust and dirt accumulate in the hose of the extraction system. In some cases, the laser system has simply failed altogether.

Not only is it important to have extraction installed, but also to have the right one for your production requirements. For example:

- High throughput lines need an extraction designed for heavy duty

- PVC production produces acidic fumes that require specific filters

- Food and beverage can coding needs specific equipment suited to aluminium debris and the demanding, often wet environment

Which extraction system to choose

An effective extraction system is required for every laser installation to optimise the output: production runs smoothly without interruption; the laser system requires no attention and the coding quality is high. Just imagine the opposite: line interruption, costs of repair, replacement, downtime, and products being rejected because the required manufacturing data is not readable.

But how do I find the perfect extraction system for my production environment? Seek expert support to help investigate your application in detail before recommending a solution. PrintDATA regularly gives companies help and advice on what is the best choice of extraction system for their requirements.

PrintDATA has a range of extraction systems available to suit your specific needs; our experts are at hand to define the ideal solution for your requirements. Please get in touch for more advice