Coding Innovations in the Brewing Industry

The beverage sector is constantly in search of higher line speeds, increased outputs, lower costs of ownership, and higher equipment efficiencies – all in the pursuit of increased market share and increased revenues and profitability. Recent coding and marking innovations designed specifically for the demanding beverage sector have been focused on reliability in printing equipment, service-free inkjet printing, as well as sustainable keg labelling.

The craft brewing industry remains a dynamic market with consumers demanding increased levels of traceability with less effort. As a result of this, printDATA continues to innovate on behalf of our beverage producing customers with new ways of doing things. Here are just a few of the recent innovations we have brought to beverage coding in Western Australia.

Keg labelling automation

Kegs must be reusable, ensuring that the industry is able to continue to provide a sustainable and environmentally-friendly way of transporting mass liquid volumes between breweries and hospitality venues. The resulting brewery demand for a traceability solution to match, means printDATA supplies a CIJ printer with washable ink. A code is applied to the top of the keg that is able to be washed off with a simple caustic wash before being refilled. This assists breweries in traceability while still supporting the retention and re-usability of existing kegs.

WA breweries have already invested in this technology to drive operational efficiencies on their keg lines and eliminate the need for manual labelling of kegs by hand. The Ax350i printer is simple, reliable, and designed for harsh, wet environments which ensures that it will operate for many years to come. In addition, the cost-effective nature of the solution has ensured that breweries have achieved a rapid return on their investment.

Vision systems and software solutions

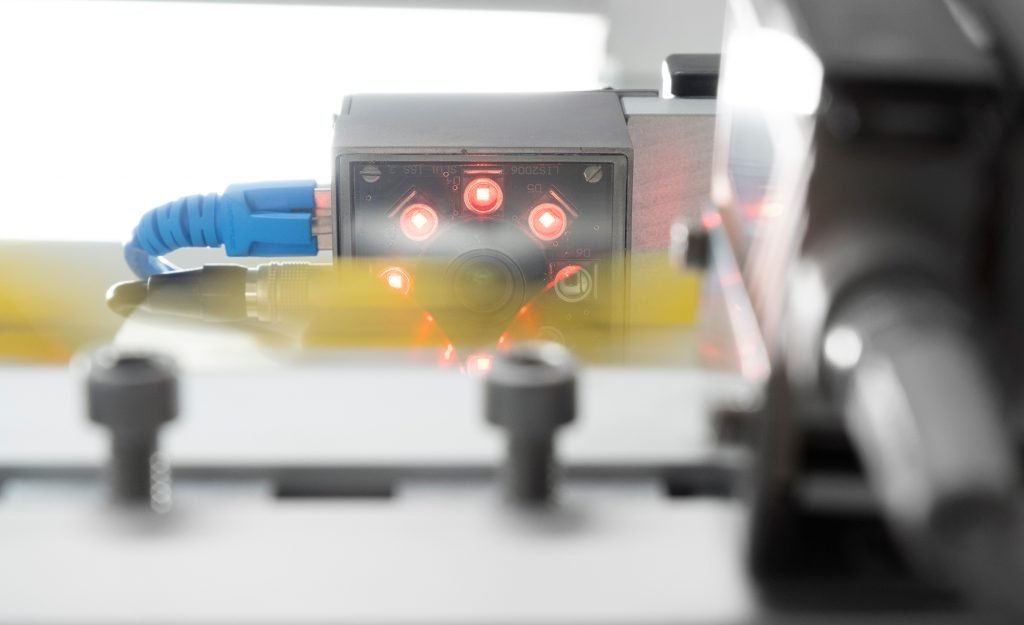

Recently, drinks producers are requesting additional accessories and software to improve the operational performance of their production lines – especially in relation to quality control. Therefore, an important addition to coding and marking equipment involves scanning and camera vision systems for code recognition and quality assurance.

Any beverage product which reaches a major retailer with either an unreadable code, incorrect code, or no code at all is liable to a significant penalty. These printing issues may be caused by simple operator errors or a printing issue from poorly cleaned printers or ageing technology. Vision systems can identify and flag any issues prior to products being palletised.

Beverage producers are also able to mitigate against operator errors by adopting an integrated software solution which can integrate with many ERP and stock control systems. It is able to coordinate communications between all on-site manufacturing equipment, thereby ensuring better management and control of the code. When coupling Domino QuickDesign software with the R-series vision system, a producer can be confident they are preventing coding issues from reaching a retailer.

Leasing Model

All of this innovation in equipment, ancillary applications and inks are rendered futile if a customer does not have capital expenditure available to purchase and invest in these solutions. This is why printDATA offers a leasing option for coding and marking equipment. Leases allow a customer to immediately start using market-leading coding and printing technology, with the equipment cost, installation, ongoing training, servicing, and repairs bundled into fixed monthly repayments.

An operational lease has many benefits for a beverage producer, including:

- Predictable fixed cost budgeting

- New equipment running on production lines – the latest technology ensures that running costs are low and line uptime is high

- Lower maintenance costs

- Less initial expense – Leases do not usually require a down payment, which means you can get a hold of your coding system upfront and with little impact on your cash flow

The disadvantages are few, but may include:

- Higher final costs – The final cost for leasing a system ends up being more expensive than purchasing it upfront

- Contractual obligations – Unless you’ve agreed to a cancellation policy, you are obligated to pay for the entire lease period even if you stop using the equipment

For smaller beverage producers, leasing is a sensible option since this provides a more cost effective way of tackling coding and marking automation. With coding and marking technology updated on a regular basis, to deliver the most efficient solutions available, a leasing option works well since it is far easier to upgrade to the latest technology.

Innovation for the Future

All in all, coding and marking onto packaging protects brands from counterfeit and product recalls and increases consumer confidence. There are a variety of technologies available but choosing the best solution for your business needs requires an understanding of packaging and production processes, business objectives, as well as satisfying the consumer, legal and environmental landscape of today’s world.

More information about all this can be found in our free download: The Brewer’s Guide to Coding and Marking.