The Five Whys: Finding the Root of the Problem

Unpredicted problems may occur in any team or process. However, problems are just symptoms of deeper issues. Fixing a problem quickly may be a convenient solution, however, it doesn’t protect your work process from recurring mistakes. This is why your team needs to focus on finding the root cause and tackling it properly.

The 5 Whys technique is one of the most effective tools for root cause analysis in the Lean management arsenal. Every team faces roadblocks in its daily work. However, using the 5 Whys will help you find the root cause of any problem and protect the process from recurring mistakes and failures.

Origin of 5 Whys

The 5 Whys method is part of the Toyota Production System. Developed by Sakichi Toyoda, a Japanese inventor and industrialist, the technique became an important part of the Lean philosophy.

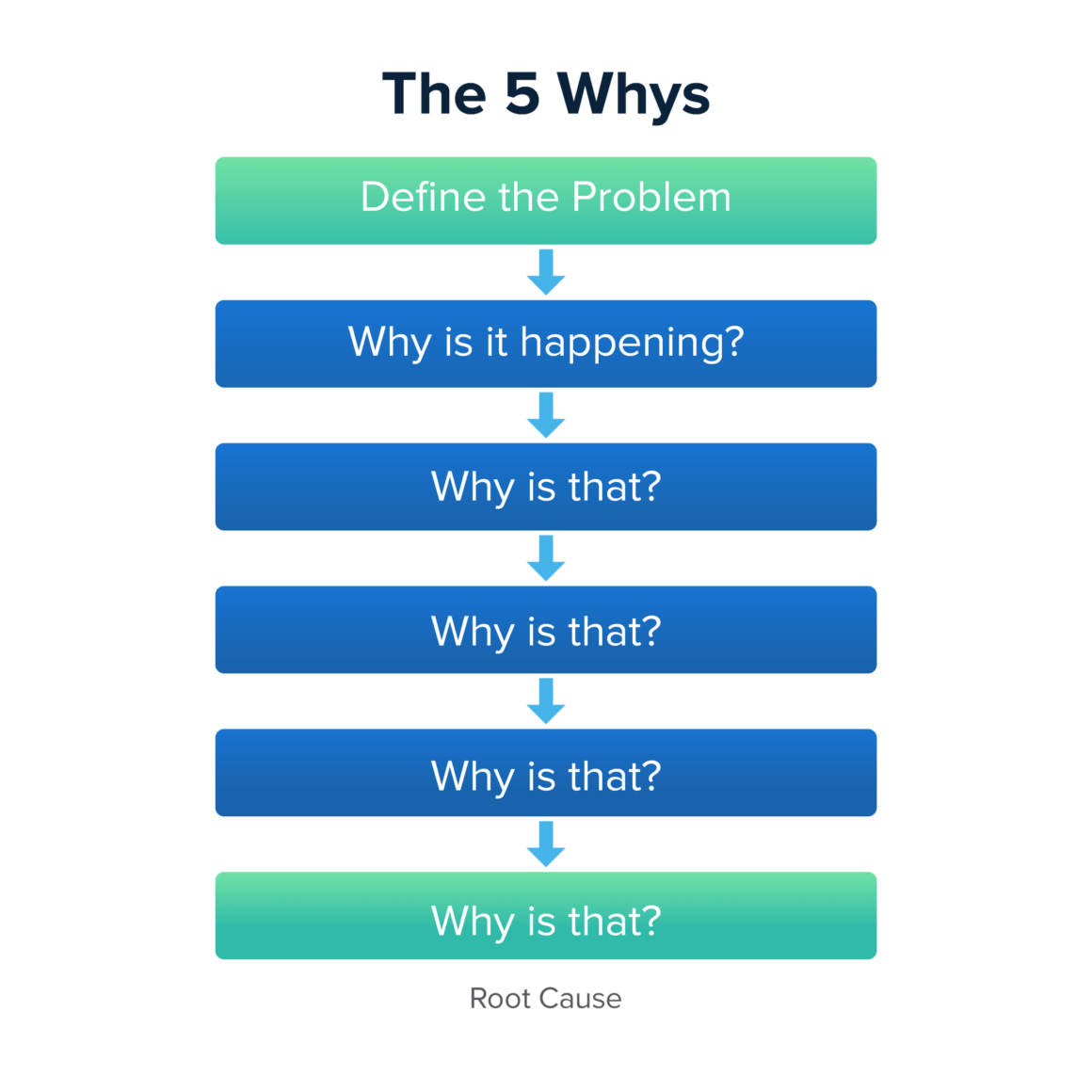

The basis of this approach is to ask ‘why’ five times whenever we find a problem. By repeating ‘why’ five times, the nature of the problem, as well as its true cause and solution, becomes clear.

5 Whys Analysis in Action

When applying the 5 Whys technique, you want to get to the problem’s source and then fix it. Usually, the 5 Whys will show you that the source of the problem is quite unexpected.

Often, issues that are considered a technical problem actually turn out to be human and process problems. This is why finding and eliminating the root cause is crucial if you want to avoid iteration of failures.

Here is an example of applying the 5 Whys:

Problem – Our client is refusing to pay for the flyers we printed for them.

Why are they refusing to pay? The delivery was late so the flyers could not be sent out on time.

Why is the delivery late? Because the job took longer than we expected.

Why did the job take so long? We ran out of printer ink.

Why did we run out of ink? The last of the ink was used on a large last-minute order.

Why was it all used in this order? Because the supplier couldn’t fulfil our ink order on time.

You can see that the root cause of the initial problem turned out to be something completely different from most expectations.

Furthermore, it is obvious that it is not a technological but a process problem. This can be typical because we often focus on the product part of the problem, as we tend to neglect the human factor.

In summary, the 5 Whys analysis aims to inspect a certain problem in depth until it shows you the real cause.

Keep in mind that “5” is not a specific number. Ask “Why” as many times as you need to complete the process and take appropriate actions. For example, in the instance above, you could continue with asking why the supplier couldn’t fulfil the ink order and continue until the real root cause of the problem is found.

How to Get Started with 5 Whys

The 5 Whys technique may help you achieve continuous improvement at any level of your organization. Here are some basic steps you need to follow.

Form a team

Try to assemble a team of people from different departments. Each representative has to be familiar with the process that is going to be investigated.

Often the cause of a problem varies across different departments in an organisation. In our example, the problem had an impact on the financial, procurement, manufacturing and delivery departments in the organisation. By forming a cross-functional team, you are going to receive unique points of view from different areas, helping you collect enough information to make an informed decision.

Define the problem

Discuss the problem with the team and make a clear problem statement. It will help you define the scope of the issue you are going to investigate.

This is important because investigating a wide scope problem may be a time-consuming exercise with blurred boundaries. Try to be as focused as possible to find an effective solution in the end.

Ask the experts

One of the key factors for the successful implementation of the technique is to make an informed decision as to what the answer to each ‘why’ question really is. This means that the process should be based on an insightful understanding of what is actually happening on the work floor. In other words, the 5 Whys process should include people with practical experience of the problem. Logically, they can give you the most valuable information regarding any problem that appears in their area of work.

Know When to Stop

You’ll know that you’ve revealed the root cause of the problem when asking “why” produces no more useful responses, and you can go no further. An appropriate countermeasure or process change should then become evident.

If you identified more than one reason for any why question along the way, repeat this process for each of the different branches of your analysis until you reach a root cause for each one.

Address the Root Cause(s)

Now that you’ve identified at least one root cause, you need to discuss and agree on the countermeasures that will prevent the problem from recurring.

Keep a close watch on how effectively your countermeasures eliminate or minimize the initial problem. You may need to amend them or replace them entirely. If this happens, it’s a good idea to repeat the 5 Whys process to ensure that you’ve identified the correct root cause.

Bear in mind that this questioning process is best suited to simple or moderately difficult problems. Complex problems may benefit from a more detailed approach, although using 5 Whys will still give you useful insights.